The history of the plant is inextricably connected with the history of the development of the railway in Belarus. The Belarusian railway originates with the commissioning on December 15, 1862 (art.) St. Petersburg-Warsaw Railway. At the same time, construction begins on a section of the Moscow-Brest Railway through the such cities as Smolensk, Orsha, Borisov, Minsk. Already in 1871, 5 km southeast of Borisov, which at that time was located only on the left bank of the Berezina, the Borisov railway station was built, and on November 16 (28) the first freight and passenger train passed through it in the direction of Minsk. So through Borisov began regular railway traffic. The construction of railways required a large quantity of sleepers.

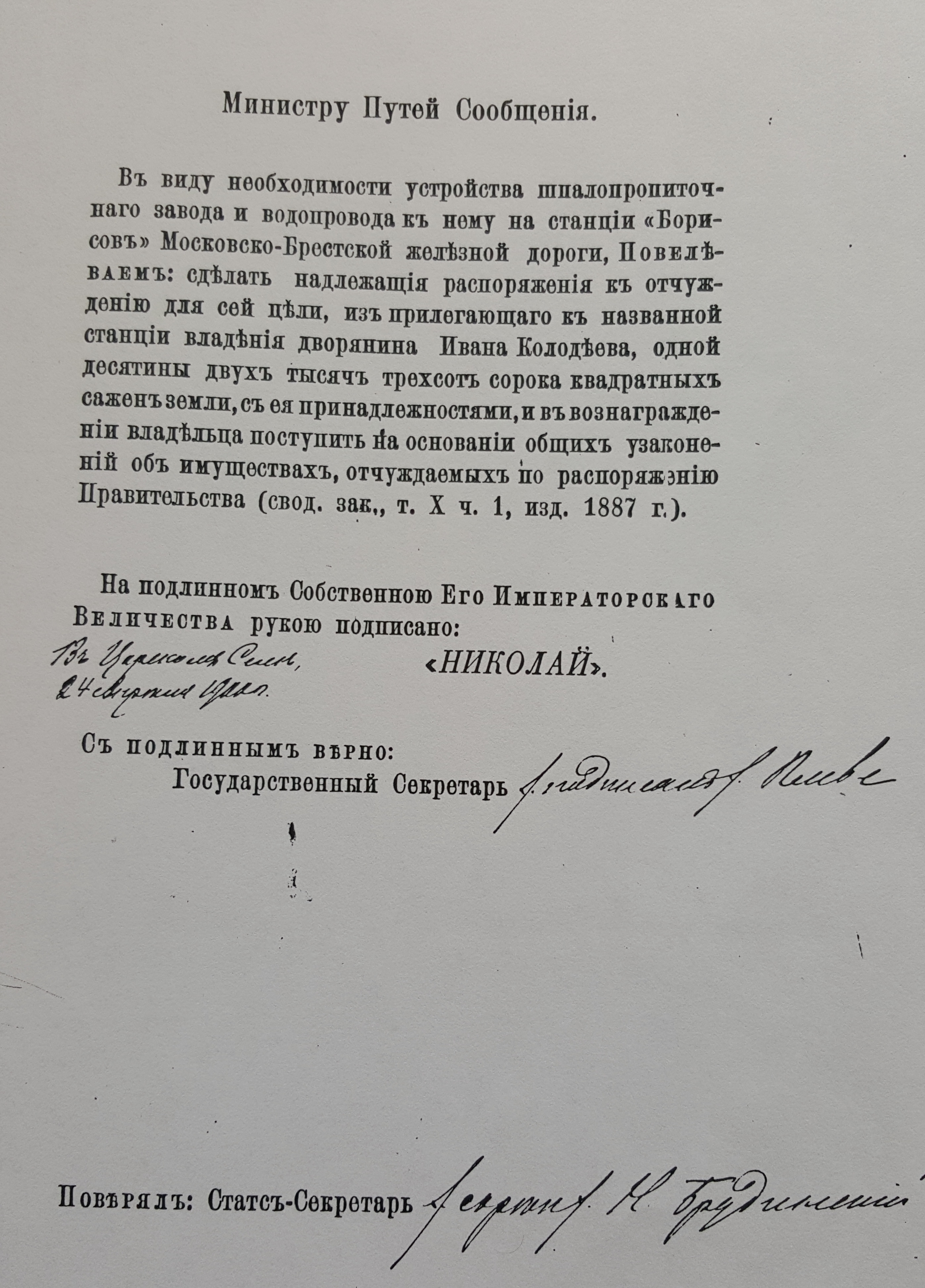

For the construction of treating plant and water supply to it at the Borisov station of the Moscow-Brest Railway, it should be necessary to occupy land with its accessories in the amount of four thousand seven hundred forty square fathoms, from the possession of nobleman Ivan Kolodeev, adjacent to the station territory.

Money was allocated for the construction of the plant, and in the period from 1900 to 1902, the Borisov treating plant was built on the site of the swamp. Its territory was a little more than two hectares with two rails, rail No. 37 "Loading" and rail No. 38 "Zavodskaya." The equipment of the impregnation processes was simple, almost artisanal, so the production was insignificant. The wood was impregnated with a tar chemical solution. According to archival data, in 1899, 22 workers and 2 employees worked at a mobile installation in Borisov, a steam engine with a capacity of 15 horsepower worked, and products at the amount of 22 thousand rubles were produced.

Meanwhile, the need of the railway for sleepers and point sleepers increased. The technology of impregnating sleepers was improved - the introduction of autoclave impregnation of wood began. In the first decade of its existence, the Borisov sleeper plant acquired and installed two impregnating cylinders, hydraulic pumps, a boiler and a machine. All these mechanisms worked for a couple. In 1910, there were already 496 workers, there was a steam engine of 120 horsepower, the amount of production of impregnated products amounted to 508 thousand rubles, which spoke of the rapid production increase of the young enterprise. In those days, wagons loaded with sleepers were fed into impregnating cylinders. They were closed with covers with 46-52 bolts. Zinc chloride, triolin, dinitrophenol began to be used for impregnation. The plant during this period worked seasonally - from April to September.

Meanwhile, the need of the railway for sleepers and point sleepers increased. The technology of impregnating sleepers was improved - the introduction of autoclave impregnation of wood began. In the first decade of its existence, the Borisov sleeper plant acquired and installed two impregnating cylinders, hydraulic pumps, a boiler and a machine. All these mechanisms worked for a couple. In 1910, there were already 496 workers, there was a steam engine of 120 horsepower, the amount of production of impregnated products amounted to 508 thousand rubles, which spoke of the rapid production increase of the young enterprise. In those days, wagons loaded with sleepers were fed into impregnating cylinders. They were closed with covers with 46-52 bolts. Zinc chloride, triolin, dinitrophenol began to be used for impregnation. The plant during this period worked seasonally - from April to September.

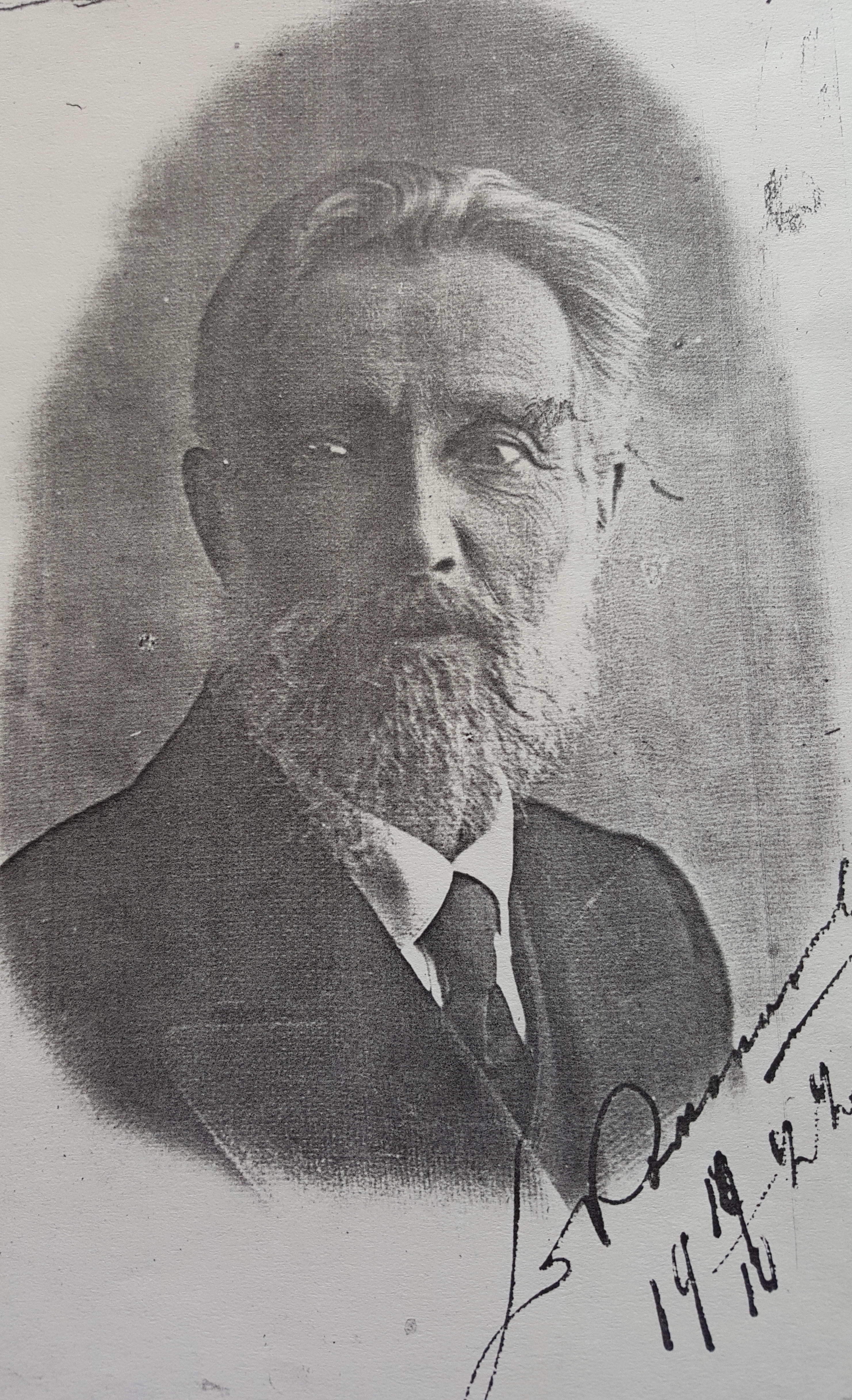

From 1911 to 1926, Dmitry Lavrovich Romanov (1826-1930) stood at the head of the Borisov trellis-propite plant. He began working in 1883 in various positions at a mobile factory. A mandatory and responsible person, he developed a lot the plant, railway and city.

From 1911 to 1926, Dmitry Lavrovich Romanov (1826-1930) stood at the head of the Borisov trellis-propite plant. He began working in 1883 in various positions at a mobile factory. A mandatory and responsible person, he developed a lot the plant, railway and city.

The labor of workers at all stages of wood processing was hand made. And this despite the fact that the technical base of the enterprise, although slowly, has improved. Sleepers were shrouded in skewers, wagons were loaded, unloaded and moved through the territory of the plant manually. Sleepers were loaded into covered cars and onto platforms also manually/hand made.

In the years of World War I most of experienced workers were called up for military service, and the plant practically doesn't work. In 1918-1920 Borisov endures the German and Polish occupations. The most part of production shops and the plant equipment are destroyed or put out of action. Many employees of the plant died on fields of civil war. During recovery of the national economy the destroyed buildings and constructions are restored, replacement of the failed equipment is made. The narrow-gage rail motor car is acquired, small shower is constructed, the part of the boggy territory is poured out, additional access roads are constructed. For simplification of work on loading of the impregnated wood to wagons the loading stage is poured out and established. Gradually working conditions of workers improved, the quality of impregnation and increase in production increased. In 1939 the part of the swamp poured out and additional access rail No. 39 "marsh" is laid. However and it doesn't allow to resolve completely an issue of warehousing of raw materials and finished goods. The additional warehouse near "The green town" is organized. For transportation of cross ties from an additional warehouse on the plant the broad gage autonomous car is bought and the rolling stock is rented. In 1939 to the Borisovsky treating plant the load-lifting crane on railway was allocated. He is used at loading of the impregnated cross bars to wagons. In 1940 the plant received two new boilers, prepared for building in 1941 of compressor installation, gantry cranes for wood loading. Capacity of plant considerably increased. Eloquently tell figures about it. If in 1938 44088 cubic meters of products were produced, then in 1940 already 61215 cubic meters of products were produced. But peace development plans weren't fated to come true.

Since the beginning of the Great Patriotic War of July on July, 1944 the plant is in the occupied territory. The German invaders tried to arrange production of impregnation of sleepers, using generally work of prisoners of war. But the underground organized on the railroad put the equipment out of action more than once, arranged raw materials arsons, carried out other acts of revenge. Before retreat, fascists took out the most valuable equipment, and destroyed the rest. Blew up the main building of the plant.

Right after Borisov's liberation the people started restoration of the destroyed economy. The enterprise had to be restored that is called from scratch: brought together the workers, invited experts, built up shops, repaired access rails, looked for the equipment across all Soviet Union. The production plan of the plant on subsidiary farm which remained in archive for 1945 is indicative in this regard. In this plan it is told that 8 hectares of cultivated area are allocated to the enterprise in the suburbs: for potatoes – 3 hectares, for vegetables – 1 hectare, forr grain 4 hectares. At the same time it was specified that there is neither draft power, nor plows, nor the cattle, nor even shovels.

Restoration continues about three years. Start-up of the plant took place in 1947: impregnated 29840 cubic meters of wood at the plan 64000. In 1950 achieved result of 118000 cubic meters at the plan of 105000 cubes. In the first, post-war years from 80 to 145 workers, from 11 to 15 technical officers and employees worked at the plant.

Small reconstruction took place in 1958: outdated impregnating cylinders with bolted fastening were replaced new with semi-automatic fastening of covers, the plant territory was expanded. Thanks to such positive changes the production increased up to 120000 cubic meters a year.

Basic changes in work happen during the seven-year-old of 1959-1965. In 1959 the reconstruction of the main building was made: wooden overlapping on reinforced concrete were changed. In 1960, construction of new shower-wardrobe began. In 1961 two hectares of the boggy territory poured out and the first semigantry crane was mounted. In 1962, works on installation of the third impregnating cylinder were conducted. Boilers were transferred to liquid fuel. The second and third semigantry crane were mounted and created. Instead of narrow-gage engines the autonomous car and a locomotive began to be used. Constructions for purification of production sewage were under construction.

In the sixties the rationalization movement developed. In 1962 from 19 improvement suggestions introduced 12, and in 1963 from the submitted 30 rationalization proposals implanted 20. Improvement suggestions helped to improve technology of impregnation of wood, to facilitate use of mechanisms and the equipment, to reduce demurrage of wagons by two and a half times. The general level of mechanization of loading and unloading works was 89.5 percent, and works with impregnation – 100 percent.

Technical re-equipment was the key to the implementation of production plans, increase in production volumes. So, if in 1961, with a plan of 92,600 cubic meters, 93,793 cubes were impregnated, then in 1965 the annual volume was already 161,000 cubic meters of output. As a result, the salary at the enterprise increased by 21.4 percent. The director of the plant in 1961-1971 was Vladimir Gurov, who paid primary attention to the technical re-equipment of the enterprise. In 1964, a third autoclave was installed in the sleeper impregnation workshop to impregnate the wooden supports of the communication line, a relay process control automation system was installed, which worked until 1990. Improved work with personnel. It is no coincidence that the team of the Borisov Treating Plant at that time won the passing Red Banner of the Belarusian Railway Administration and the Dorprofsoyuz five times.

Technical re-equipment was the key to the implementation of production plans, increase in production volumes. So, if in 1961, with a plan of 92,600 cubic meters, 93,793 cubes were impregnated, then in 1965 the annual volume was already 161,000 cubic meters of output. As a result, the salary at the enterprise increased by 21.4 percent. The director of the plant in 1961-1971 was Vladimir Gurov, who paid primary attention to the technical re-equipment of the enterprise. In 1964, a third autoclave was installed in the sleeper impregnation workshop to impregnate the wooden supports of the communication line, a relay process control automation system was installed, which worked until 1990. Improved work with personnel. It is no coincidence that the team of the Borisov Treating Plant at that time won the passing Red Banner of the Belarusian Railway Administration and the Dorprofsoyuz five times.

In 1971-1983, the enterprise was led by Semyon Yakovlevich Eremkin. Under his command, new diesel locomotives and gantry cranes appeared, workplaces were equipped with modern electrical equipment and computing machines, the fleet of working machines was updated, an administrative building and a fire station were built.

Subsequent years brought another achievement. In 1983-1987, under the leadership of Alexander Sergeyevich Sukhodolsky, a large-scale reorganization of the track economy was carried out at the plant. Special attention was paid to the technical improvement of technological processes. KKS-10, KK-20, KPB-10 cranes are installed and put into operation. Narrow gauge diesel locomotives are replaced by TU-7a and T7 diesel locomotives.

In 1987, the company was headed by Gennady Fedorovich Morozyuk G.F. Largely thanks to him, the experiment began at the Borisov Treating Plant to work in new economic conditions. As a result, planning improved, the rights of the enterprise expanded, the interest of structural divisions and the whole team increased as a result of their work. In order to improve working conditions, the plant built new treatment facilities, made a track reconstruction of the pre-cylinder platform and track narrow gauge, acquired self-propelled rifle railway and automobile cranes, and other equipment. At the same time, they strengthened the production raw materials base at the Priyamino station. In 1989, the company acquired Iskra computers, which greatly facilitated and accelerated the process of processing documents. In 1990, the enterprise impregnated 178 thousand cubic meters of wood. The plant worked around the clock, providing all of Belarus with its products, almost a third of the needs of Ukraine, Lithuania, Latvia and other consumers.

In 1994, the plant acquired and installed an experimental plant for impregnating wood with ecological pure antiseptic together with the Institute of Heat and Mass Exchange of the National Academy of Sciences of Belarus.

The large reconstruction of the Borisov treating plant began to be successfully carried out under the leadership of director Pashkeev A.I., who took over the management functions of the enterprise in 1997 (since 1986 he worked as the chief engineer of the plant). The chief engineers during this period were Soroka V.N. (from 1997 to 2008), Novik V.P. (since 2008).

At the raw material base located at Priyamino station, in January 1997 a sawmill was created, which becomes an auxiliary unit of the plant producing unpowered sleeper products. Sawmill frames LRV-1 and R63, the Kara longitudinal sawing machine were purchased. The productivity of the workshop was 800-1000 m3 of roundwood sawing. After 2000, the sawmill R63, two MG-6200 belt machines were additionally installed. The volume of wood sawing reached 1900 m3. During this period, the working conditions of the workers of the workshop were improved: the household room, the room for drying workwear, and the room of craftsmen were expanded due to the construction of an extension. In 2004, the reconstruction of production premises, the territory of the workshop, warehouse of raw materials and finished products was completed. In 2007, the sawmill was relocated to the main territory of the plant, where a new sawmill was organized in the hangar, and under the "factory crane" a warehouse of raw materials and finished products. New Wood-Mizer equipment was purchased: two tape machines LT70 and a multi-saw machine, new refining equipment, and staff was trained to work on new equipment. With the transition of the workshop to the plant, there was a significant improvement in the labor of the site employees: better living conditions, physical activity in the production process is reduced; compactness of production was achieved, transportation costs for delivery of products to the plant were excluded. During this period, the sawmill was led by: Mayevskaya A.A. (from 1997 to 1999), Lyutomsky Yu.N. (from 1999 to 2011), Likhachevsky N.V. (from 2011).

The project for the reconstruction of the plant in 2000 passed an examination and was accepted into production. The Beltransstroy was appointed the general contractor, headed by N.M. Shapovalov, a professional leader and a high-ranking person. The performer was SPM-738, whose head was G.A. Savchenko.

On August 3, 2000, in honor of the 100th anniversary of the Borisov Treating Plant, the first trial pile of the new workshop was clogged. This event rightfully went down in the glorious history of one of the oldest enterprises of the Republic of Belarus.

The first stage of the reconstruction of the enterprise included the construction of warehouse for natural drying of sleepers for 60 thousand cubic meters of wood. The territory of the ASG warehouse was filled by half a meter. ASGs were delivered by dumkar swivels from the quarry of the urban village of Radoshkovichi. Water collection trays with treatment facilities were laid. At the same time, a fire extinguishing system was installed: an annular water supply with a diameter of 200 millimeters was laid with the installation of 24 monitors. Lightning protection of the warehouse was created, lighting was installed, a fire pond with a fire extinguishing pump station was built. Three gantry cranes KKS-10 were mounted at the sleepers drying warehouse. The area around the drying warehouse was landscaped, asphalt was put on the roads.

The second stage of reconstruction included the construction of a domestic building, the installation of treatment facilities and a mortar impregnation workshop.

The third stage was the completion of the construction of the wood impregnation workshop. In this workshop, a pass-through type autoclave was mounted with a working pressure of 16 atmospheres. The workshop was divided into several sites: storage sites for unpowered and finished products, a machine room with a control panel, mechanical workshops, a thermal unit and a ventilation system with afterburning of emissions. Automation of process control allowed using a computer to control the ventilation system and wood impregnation processes.

In the impregnation workshop, a line of end fastening of sleepers with metal plates was installed, developed and manufactured by the Baranavichy Automatic Lines Plant.

The fruits of reconstruction allowed to improve the environmental situation. The antiseptic stopped getting into groundwater and into the Berezina River. Emissions of harmful substances into the atmosphere have significantly decreased. The quantity of work places with increased content of harmful substances has decreased. The work of the rafters of finished products was significantly facilitated. Improved fire safety system. Impregnation of wood began to be carried out by various antiseptics.

The introduction of cooling water supply for the operation of pumping pumps and vacuum machines served to reduce water discharges to treatment facilities to 1000 cubic meters per month. Therefore, the treatment facilities were transferred to work in a single-shift mode, and the vacated personnel replenished the mechanical and impregnation workshop.

Many innovations allowed to abandon outdated production operations. So, with a change in the impregnation of wood, the need to use steam to warm up the antiseptic disappeared, which caused the decision to reconstruct the boiler room. The Belzheldorproekt Institute has developed a modular type boiler house with two natural gas-fired water-heating boilers. This modular installation was manufactured by specialists of Mobile Energy Systems OJSC in the city of Baranavichi, and Dorstroymontazh replaced the networks and thermal units.

In January 2008, a new modular boiler house was introduced. The operational personnel who worked in the old boiler room, where fuel oil was used, were transferred to round-the-clock duty, as well as to the observation room for the fire extinguishing system of the impregnation workshop. With the new modular boiler house, the consumption of service water decreased. Heat units with automatic temperature control system were installed in each heated room.

Since 2000, over 600 thousand sleepers have already been impregnated annually at the Borisov treating plant.

During this period, work is underway to introduce new types of antiseptics, new types of impregnation were worked out. At the same time, emphasis was placed on saving energy resources, economical production, and further improvement of working conditions. The use of water-soluble antiseptic has become a priority at the Borisov treating plant. Specialists of the Belarusian Technological University provided substantial assistance in introducing new antiseptics at the enterprise. In 2009, the company developed and introduced new impregnating bioprotective solutions based on TANALITH E antiseptics that do not require heating, and in 2010, the IPTF Protective Agent impregnation composition was developed and introduced at Borisov Treating Plant OJSC.

In 2013, a modernization program was implemented: the "Line of surface knitting of sleepers and clogging of end plates" was introduced. Due to the introduction of this technology, energy costs for impregnating sleepers have been reduced, their life has been increased.

MANAGERS OF PLANT:

ROMANOV Dmitry Lavrovich (1826-1930) - director/manager since 1911 to 1926;

ROMANOV Dmitry Lavrovich (1826-1930) - director/manager since 1911 to 1926;

SMIRNOV A. - director in the 30s of the twentieth century;

SMIRNOV A. - director in the 30s of the twentieth century;  DORONIN - director in the 50s of the twentieth century;

DORONIN - director in the 50s of the twentieth century;

KAPLUN Samuel Yakovlevich - director of the plant in the 50s.

KAPLUN Samuel Yakovlevich - director of the plant in the 50s.  GUROV Vladimir Parfyonovich - director since 1961 to 1971;

GUROV Vladimir Parfyonovich - director since 1961 to 1971;  EREMKIN Semyon Yakovlevich (1931-1993) - director since 1971 to 1983;

EREMKIN Semyon Yakovlevich (1931-1993) - director since 1971 to 1983;

SUKHODOLSKY Alexander Sergeevich - director since 1983 to 1987;

SUKHODOLSKY Alexander Sergeevich - director since 1983 to 1987;  MOROZYUK Gennady Fedorovich (1952- 2011) - director since 1987 to 1997;

MOROZYUK Gennady Fedorovich (1952- 2011) - director since 1987 to 1997;  PASHKEEV Alexander Ivanovich (1954) - Director since 1997 to 14.07.2020.

PASHKEEV Alexander Ivanovich (1954) - Director since 1997 to 14.07.2020.